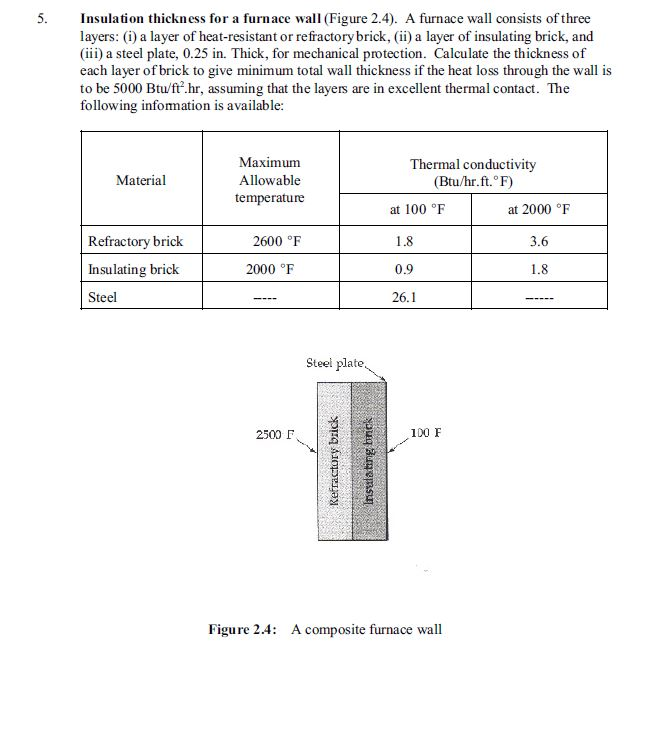

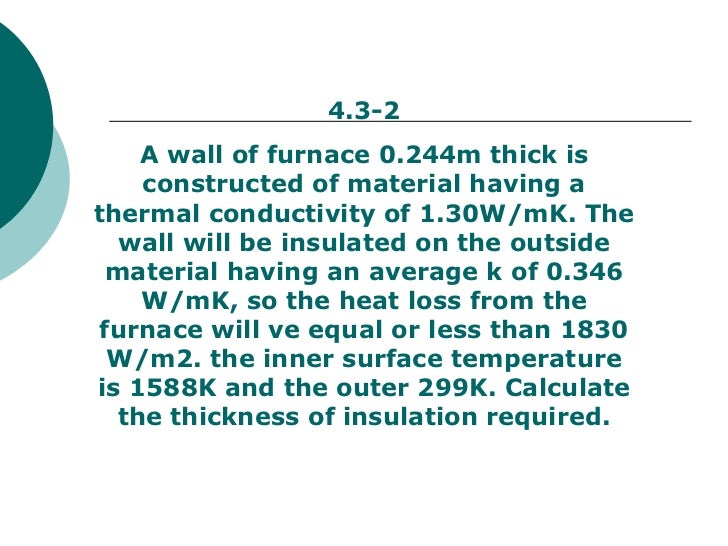

Furnace Insulation Thickness Calculation

Calculate overall heat transfer coefficients for walls or heat exchangers.

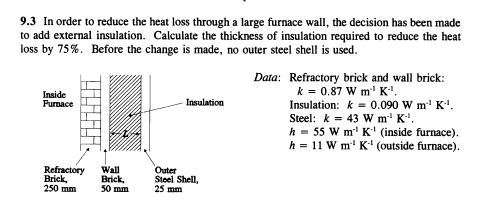

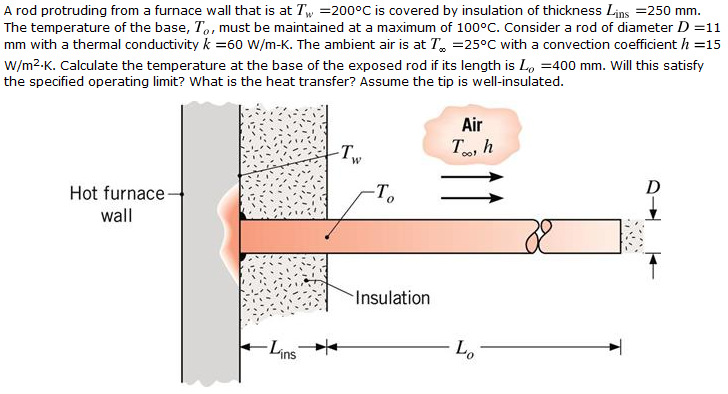

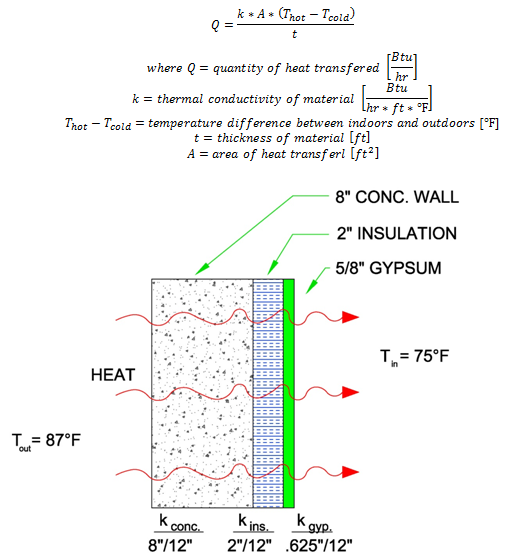

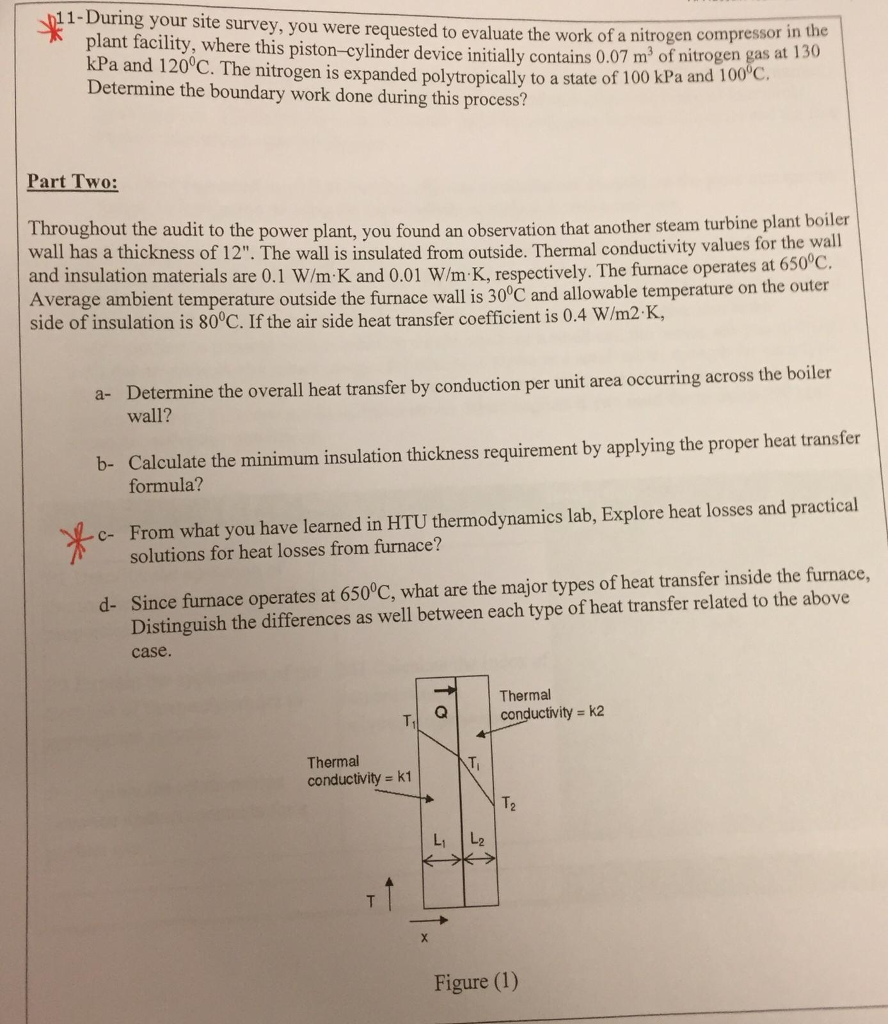

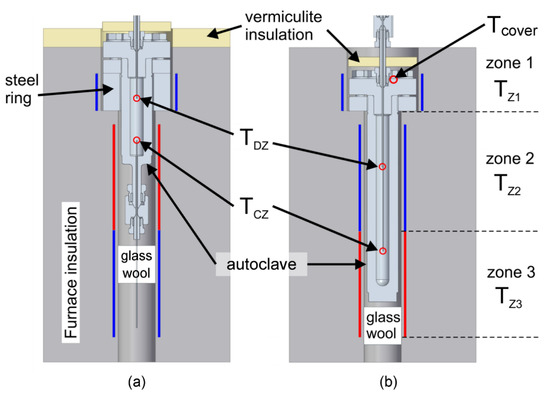

Furnace insulation thickness calculation. A diffusion tight application is a must minimum insulation thickness 7 6 mm tube diameter 25 4 mm. Piping recommended insulation thickness. Very hot systems like hot water and steam systems should also be insulated to avoid potential personal. The wall of a furnace comprises three layers as shown in the figure.

General formula to calculate minimum insulation thickness required to prevent condensation t k r t1 t2 t3 t1 where t insulation thickness in k thermal conductivity r surface temperature resistance t1 dew point temperature. Extra margin must be taken on insulation thickness as sometimes conducting heat transfer through insulation may become higher than convective heat transfer due to air on outside wall of insulation. Recommended insulation thickness of heating systems like hot water low medium or high pressure steam systems. Thermal conductivity of perlite insulation temperature and k values.

Calculate the thickness of each layer of brick to give minimum total wall thickness if. Hence insulation thickness ri rp 0 2302 0 1524 0 0777. A furnace wall consists of three layers. Thermal conductivity of the insulation material for the temperature range of the pipe can be taken as 0 04 w m k.

Recommended insulation thickness of heating systems like hot water low medium or high pressure steam systems. 3 2sufficient thermal insulation thickness tm 6 c φ 65 td 22 8 c ta 30 c r flex st kalınlık 9 mm ts 23 6 c td 22 8 c thermal insulation material with a high µ value no condensation. I a layer of heat resistant or refractory brick ii a layer of insulating brick and iii a steel plate 0 25 in. The third layer is a plate of 6 35 mm thickness of steel thermal conductivity 45 w m k.

Insulation thickness 77 7 mm. Check list information required for the design of cold insulations information to be provided by client or contractor. To calculate the insulation thickness sufficient to prevent condensation formation on the surface the fac tors given in table 1 must either be known be assumed or agreed with the operator of the installation. The pipe size is 8 and the maximum allowable temperature of outer wall of insulation is 50 0 c.

Thick for mechanical protection as shown in fig. This calculation determines the ideal thickness of water piping insulation for efficiently and economically preventing a heat transfer from outside to inside and keeping the water transported within cool it does not determine the thickness of insulation designed to keep condensate or other fluids from losing heat. Calculate insulation thickness minimum value required for a pipe carrying steam at 180 0 c. The heat loss from steam per meter of pipe length has to be.