Forming Plywood To Form Roof Substrate

Engineered wood also called mass timber composite wood man made wood or manufactured board includes a range of derivative wood products which are manufactured by binding or fixing the strands particles fibres or veneers or boards of wood together with adhesives or other methods of fixation to form composite material the panels vary in size but can range upwards of 64 by 8 feet 19 5.

Forming plywood to form roof substrate. This guide will explain the different uses of plywood as well as popular plywood sheet sizes and its rating and grade system so that you can choose the best plywood for your project. Plywood is a necessity in many diy and construction projects but not every type of plywood works for every project. Click to add item roseburg pourmor triple 3 3 4 x 4 x 8 mdo concrete forming plywood to the compare list. Apa plyform panels however are specifically designed to withstand the wear and tear of repeated concrete pours as well as to provide a smoother and more consistent finish to the concrete s surface.

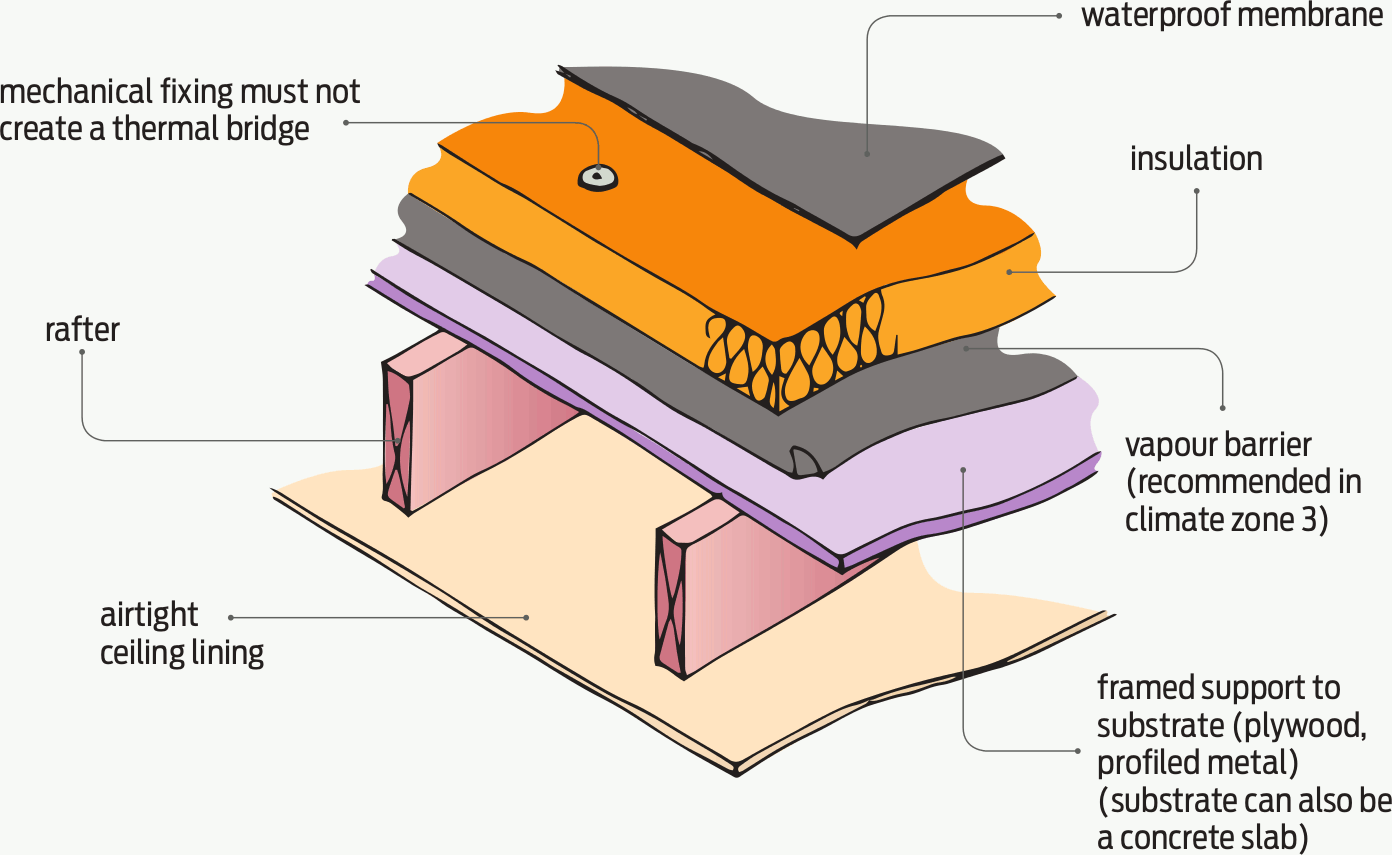

Formall is a class 1 concrete form plywood designed to provide superior performance in the most demanding applications. Nearly all types of plywood panels can be used in concrete forming from common roof and wall sheathing to sanded panels. Structural roof substrate materials include metal timber or concrete based products and are detailed below. To read my first two articles roofs are systems and roof decks see the january february issue page 52 and the march april issue page 54 respectively for the purpose of this article we will define the substrate board as the material that is placed upon the roof deck prior to the placement of.

The many types of plywood can differ in materials number of layers rating and grade. These plies are then laminated together using heat pressure and glue with the grains aligned perpendicular to each other to provide strength from both directions. Concrete form plywood panels manufactured in conformance with the requirements of ps 1. Steel deck forms feature a steel frame a plywood substrate and a resin surface finish.

The third installment in my series on the roof system is about the substrate board. When using steel forms designers usually are concerned more about panel joint and tie hole locations than finish. Standard thicknesses include 19 32 5 8 23 32 and 3 4 in standard 4 x 8 sheets. By submitting this rebate form you agree to resolve any disputes related to rebate redemption by binding arbitration and you waive any right to file or participate in a class action.

The minimum plywood for roofing. What are the different roof substrate materials used. Plywood is made from thin plies that are shaved from logs. Form manufacturers generally require thin film reactive type form release compounds for good form release.

Siding span siding span is a span rated. Plywood is a popular construction material for both residential and non residential roof sheathing.