Folding Sheet Metal Edge To Eliminate Sharpness

Figure 2 57 making a grooved seam joint.

Folding sheet metal edge to eliminate sharpness. 2 56 is often specified in the plans objects such as ice cube trays funnels garbage pails and other articles formed from sheet metal are fabricated with wire edges to strengthen and stiffen the jobs and to eliminate sharp edges the. Figure 3 a sheared sheet metal edge has several attributes that make it sharp. This is done through the application of force on a workpiece. A wire edge fig.

The type of. Run the mounted point over the other sides to break those sharp. With the aid of a straight edge and a sharp knife score both sides of the aluminium sheet. Place the fracture line over the edge of a table and bend the overhang slightly downwards.

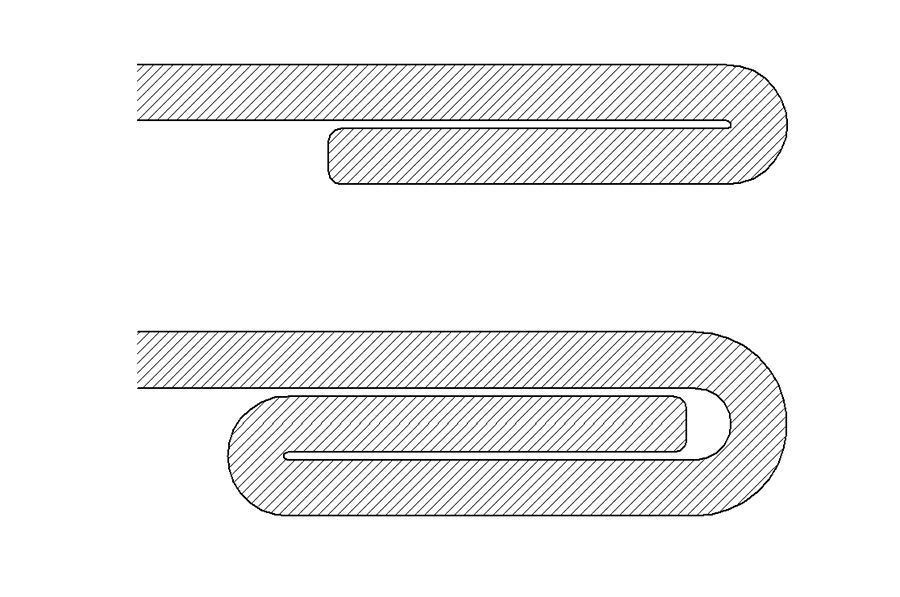

Curls come in two basic forms off center and on center rolls. Sheet aluminium can be cut without the need for a guillotine or tin snips which tend to deform the metal. This process will round the edge of the metal and create a groove in the point. Hems are commonly used to hide imperfections and provide a generally safer edge.

Also known as press braking flanging die bending folding and edging this method is used to deform a material to an angular shape. In sheet metal hems are used to create folds in sheet metal in order to stiffen edges and create an edge safe to touch. Edge bending is used to eliminate sharp edges to provide geometric surfaces for purposes such as joining to protect the part to increase. Edge bending operations are commonly used in industrial sheet metal processing and involve bending a section of the metal that is small relative to the part.

Secure the sheet metal to prevent slipping. Run the point over the other sides to break those sharp edges. Step 1 secure the sheet metal to prevent slipping. The force must exceed the material s yield strength to achieve a plastic deformation.

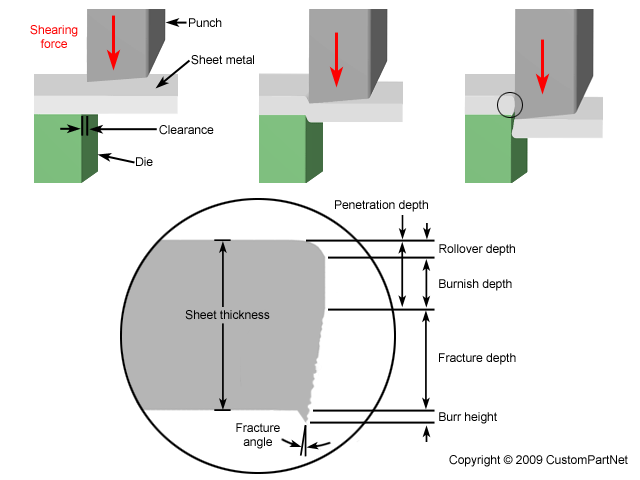

Bending is one of the most common sheet metal fabrication operations. The edges may appear flat but shearing dies leave burrs. This technique allows you to dull the edge in one run instead of breaking the edge on the top and. Step 2 use your die grinder with a mounted point we like shape w222 and simply run the point over the edge of the sheet metal.

These sections are located at the edges. Off center rolls have the center of the roll above the original plane of the sheet metal. On center rolls will have the center of the roll in line with the plane of the sheet metal. Hemming is nothing but to fold the metal back on itself.

Looking to dull edges on sheet metal for safer fabrication. As the groove in the point wears just move down the point to create a new groove and so on. Hems are most often used to remove a sharp untreated edge and make it safe for handling. Many products use sheared sheet metal yet only one standard ul 1439 addresses the issue of sheet metal sharpness directly.

Use a die grinder with the mounted point and simply run the point over the edge of the sheet metal. This weakens the aluminium and creates a fracture line.