Floating Roof Tank Landing

A floating roof should be landed only if the tank is to be removed from service for routine inspection or maintenance activities.

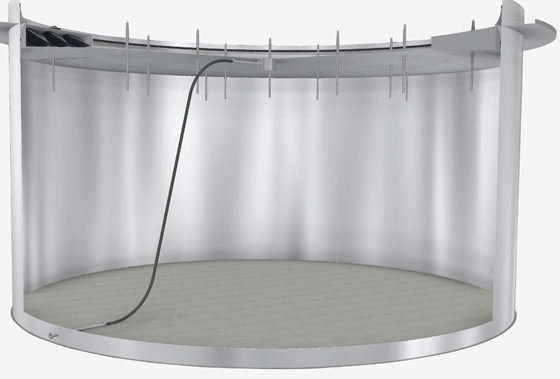

Floating roof tank landing. There was a fatality on a large diameter floating roof tank when a contractor died under the weight of the roof plates which collapsed on him. The roof rises and falls with the liquid level in the tank. It consists of an open topped cylindrical steel shell equipped with a roof that floats on the surface of the stored liquid. Another option to consider includes reconfiguring the tank bottom to eliminate the presence of a heel after the discharge pump loses suction.

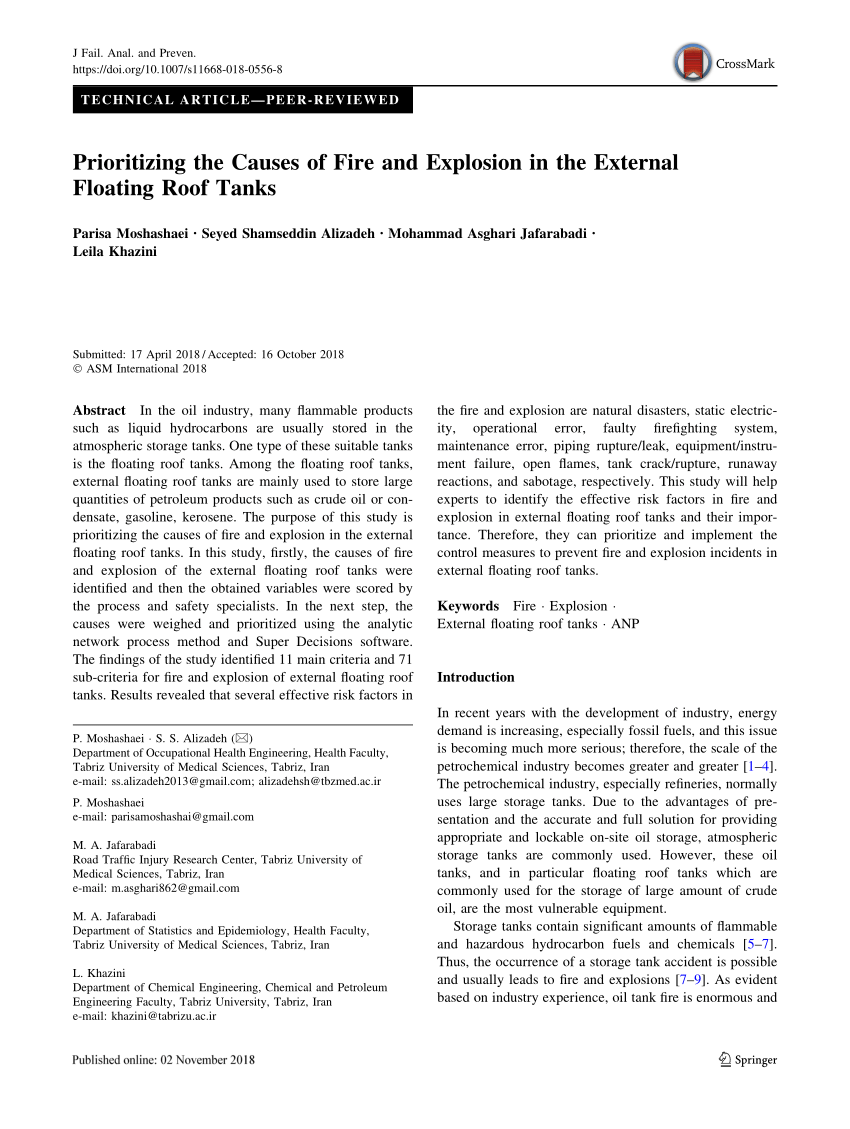

Floating roof landing losses21 when using floating roof tanks the roof floats on the surface of the liquid inside the tank and reduces evaporative losses during normal operation. This approach requires frequent trips to the tank especially around significant weather events. However when the tank is emptied to the point that the roof lands on deck legs there is a period where the roof is not floating and. Failures of floating roof primary and secondary seals foam filled or liquid filled have been a significant concern.

Landing a floating roof on low legs is an excellent and easy way to lower emissions during rvp landings. It consists of an open. A floating roof tank is a storage tank commonly used to store large quantities of petroleum products such as crude oil or condensate. Various aspects of the floating roof tank working like the operation.

The equations for routine emissions from internal floating roof tanks assume that the tank has open vents in the fixed roof. The floating roof must be provided with landing legs that are designed to support the external floating roof under a uniform design load of at least 25 psf api 650 appendix c 3 10. Section 7 1 3 8 2 addresses estimation of emissions when an internal floating roof tank has closed pressure vacuum vents. Tank wall abnormalities preventing the roof from floating freely roof access rolling ladder not moving freely traditionally visual inspections have been performed by climbing the tanks.

G internal floating roof tanks with closed vent systems. Poor tank turnaround practices with inadequate checking of roof supports. This decreases the size of the vapor space and corresponding losses. The floating roof tank animation describes the working principle in the training module.